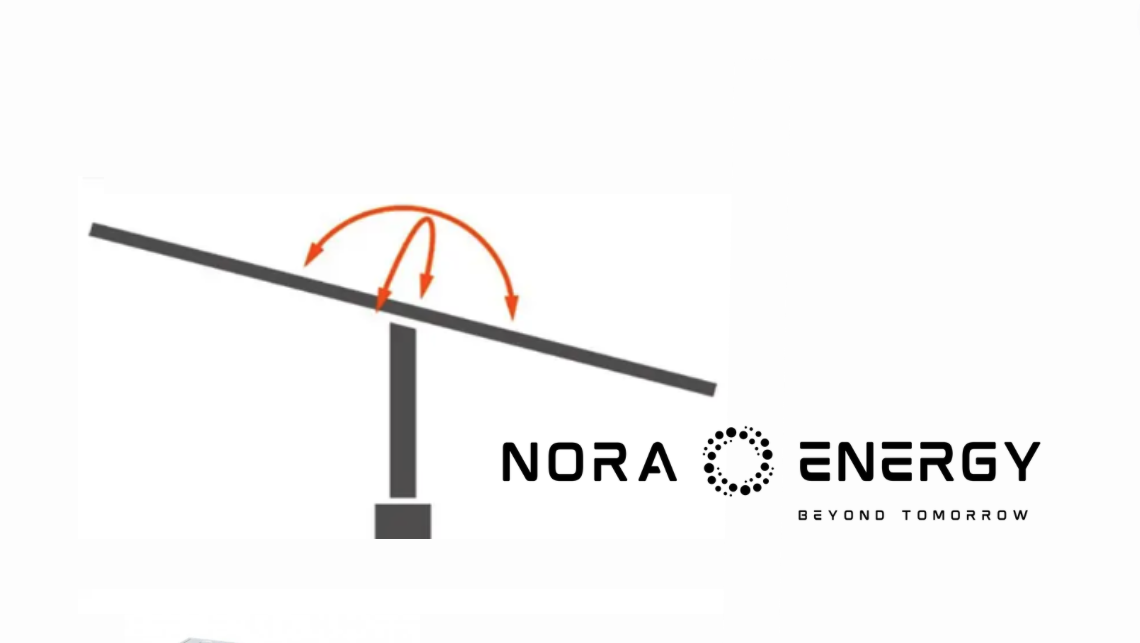

Two-axis solar tracker and 4 panel holder with main pole and ground fixing screws.

Description

Fully automated two-axis solar tracking system

A fully automated dual-axis solar tracking system for 4 panels. The system uses GPS-controlled two-axis tracking to fully track the sun throughout the day, increasing solar electricity generation by up to 66%.

Dual-axis solar tracking system

Dual-axis or dual-axis solar tracking system with better than 0.5 degrees accuracy and support structure for 4 solar panels measuring 1 m x 1.7 m and weighing up to 22.5 kg each. In total, for a solar panel surface of 6.5 m². Suitable for photovoltaic (PV) panels.

The maximum wind speed allowed in the working position is 50 km/h. The maximum wind speed allowed in the safe (horizontal) position is 120 km/h. On an annual basis, with the two-axis system you can get 7% more energy compared to a single-axis system and up to 66% more energy compared to a fixed solar system. The anchoring screw and the main pole are part of this solar tracking package.

Anti-shading software function for solar tracking system included.

Please check compatibility of solar panels with this tracking system. If your panels are larger, we strongly recommend that you consider adding a Bar Arm Bracket to ensure proper mounting.

Technical Specifications

Mechanical Capabilities

| Number of rotation axes | Dual-Axis |

|---|---|

| Hour angle limit | 100°, *software and hardware limit 50E to 50W* |

| Elevation angle | 15-90°, *start adjustable* |

| Type of angle hour motor | Linear motor SHMS501M2 with 510 mm stroke |

| Elevation angle motor type | Linear motor SHMS501M2 with 510 mm stroke |

| Diameter and length of the hour angle shaft | Ø46 mm, L=400 mm (fixed) |

| Backstructure | 2 pcs. Ø1600 (4.8 m² and 6 pieces) Ø1500 (1.9 m² and 6 pieces) Ø2000 (V) (1V) |

| Backstructure clamp type | Toothed scissor clamps - 16 pcs. |

| Tube diameter | Ø76×1.3 mm with reduction up to Ø68 mm (not included in kit) |

| Max. solar panel size | 4 pcs. of 1 m x 1.70 m totalling 6.5 m². |

| Max. weight of a solar panel | 4 pieces per 10.9 kg |

| Estimated lifetime | 800-1000h motor runtime (replace DC motor after 8 years if every day a cycle), replace backup battery every 3-5 years in battery mode, the rest 25 years |

Positioning System Data

| Tracking Accuracy | < 0.05° (optional < 0.1° - for additional payment) |

|---|---|

| Operating Protocol | TAdAPS (Time Derived Astronomical Positioning System) |

| Type of positioning system | Servomotor positioner with TAdAPS as main logic function. |

| Positioner type | Supo |